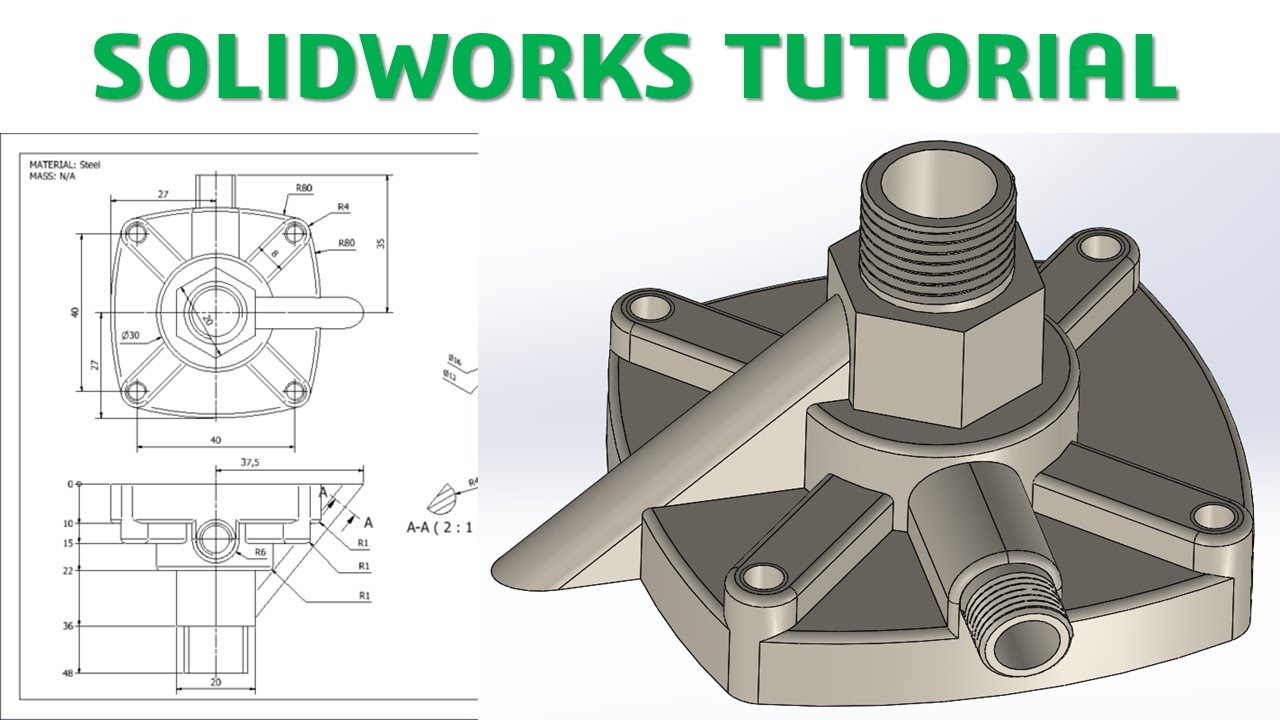

Our engineers have developed FikusWorks with the goal of reducing the steps users must take to program a part. Thanks to FikusCloud online services, FikusWorks keeps postprocessors and technology boards permanently updated: updates to your wire machines will be immediately supported by your FikusWorks solution.

The deep knowledge of this technology and the inclusion of specific technological tables and post-processors for most of the machines on the market, allows Fikus to provide ultra-precise machining with the best surface quality. The Phases to Geo & Geo to Phases function (day/night option) allows maximum flexibility to organize machining processes helping to increase productivity by freely managing which processes will be performed without the need for operators to be present. Control every cutting parameter: offsetting, automatic threading, position of the wire, constant and variable taper, and our latest improvement: Auto-fix, control of the remnant size for a better part disengage. With FikusWorks you can machine any contoured mold, die, core, cavity shape or profile.

Our close work with the technology leaders put FikusWorks ahead of other CAM packages when it comes to get the most out of your wire EDM machine. Expert knowledge of the wire EDM technologyįikusWorks is leading innovation in CAD/CAM for wire EDM machining because of its acknowledged expertise in controlling this extremely accurate and sophisticated technology.

0 kommentar(er)

0 kommentar(er)